-

English

English -

简体中文

简体中文

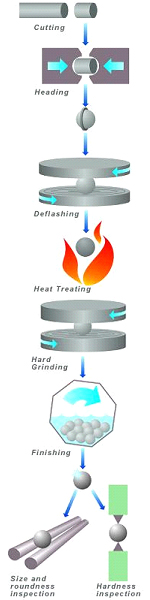

Processes

All steel balls are made by 6 steps: Heading, soft grinding, heat treatment, flashing, flashing, hard grinding, inspection and packing.

|

Raw Material,wire drawing: the wire rod is drawn to the required size,in closer tolerances so that it can be used in cold forging. |

|

Cold forgig: Calculated length of wire is sheared and cold forged in a close die to give it the spherical shape. |

|

|

Flashing: The rolling between plates with concentric grooves in order to eliminate the heading witness marks and to increase the precision of the ball, In this operation the spheres are ground between two concentric pressure plates to correct the sherical shape and remove the seam formed in the cold forging. |

|

|

Heat treating: Carbon steel balls are next carburized and hardened. Heat treatment imparts the desired hardness and case depth. |

|

|

Descaling: This step removes the residues and by-products for the preceding process. |

|

|

Hard Grinding: Here the hardened balls are ground to improve suface finish and geometrical parameters. Several careful grinding processes with ceramic wheels lead to a higher size precision preparing the balls for the next final lapping operation. |

|

|

Finishing: Proprietary chemical and mechanical processes give the balls their final micro-smoothed finish, increasing wear resistance and product longevity. |

|

|

Inspecting: All products pass through at least two 100% inspection stages, using proprietary,automated inspection processes. |