-

English

English -

简体中文

简体中文

|

Grade

|

Variation of

ball diameter VDws Max. |

Deviation from

sherica from tDw Max. |

Surface

roughness Ra Max. |

Lot diameter

Variation VDwl Max. |

|

G3

|

0.08

|

0.08

|

0.010

|

0.10

|

|

G5

|

0.13

|

0.13

|

0.014

|

0.25

|

|

G10

|

0.25

|

0.25

|

0.020

|

0.5

|

|

G16

|

0.4

|

0.4

|

0.025

|

0.8

|

|

G20

|

0.5

|

0.5

|

0.032

|

1

|

|

G24

|

0.6

|

0.6

|

0.040

|

1.2

|

|

G28

|

0.7

|

0.7

|

0.050

|

1.4

|

|

G40

|

1

|

1

|

0.060

|

2

|

|

G60

|

1.5

|

1.5

|

0.080

|

3

|

|

G100

|

2.5

|

2.5

|

0.100

|

5

|

|

G200

|

5

|

5

|

0.150

|

10

|

|

G500

|

12.5

|

12.5

|

|

25

|

|

G1000

|

25

|

25

|

|

50

|

|

Unit:um

|

|

|

|

|

|

Symbols

|

||

|

|

|

|

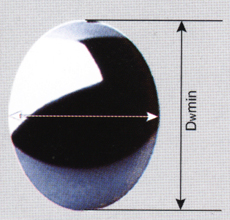

Ball diameter variation |

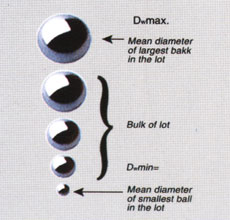

Lot diameter variation

VDwl=Dw max.-Dw min. |

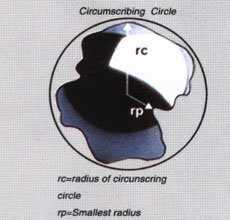

Deviation from

spherical form |

|

Ball mean diameter

Dwm=Dw max.+Dw min. 2 |

Lot mean diameter

Dwml=Dwm=Dw max.+Dwm min. 2 |

tDw=rc-rp

|

ANSI/AFBM Std 10-1989(Revision of 1983)

|

Ball Grade

|

Allowable Ball Diamtter Variation

|

Allowable Deviation From Spherical Form

|

Maximum Surface Roughness Arithmetic Average

|

Allowable lot Diameter Variation

|

Nominal Ball Diameter Tolerance

|

Allowable Ball Guage Deviation

|

Contaier Marking Increment

|

|

|

VDWS(um)

|

△Rw(um) |

Ra(um)

|

VDWL(um)

|

(um)

|

△S

|

|

|

3

|

0.08

|

0.08

|

0.012

|

0.13

|

*

|

+0.75 -0.75

|

0.25

|

|

5

|

0.13

|

0.13

|

0.02

|

0.25

|

*

|

+1.25 -1.00

|

0.25

|

|

10

|

0.25

|

0.25

|

0.025

|

0.5

|

*

|

+1.25 -1.00

|

0.25

|

|

16

|

0.4

|

0.4

|

0.025

|

0.8

|

*

|

+1.25 -1.00

|

0.25

|

|

24

|

0.6

|

0.6

|

0.05

|

1.2

|

*

|

+2.50 -2.50

|

0.25

|

|

48

|

1.2

|

1.2

|

0.08

|

2.4

|

*

|

*

|

1.25

|

|

100

|

2.5

|

2.5

|

0.125

|

5

|

±12.5 |

*

|

|

|

200

|

5

|

5

|

0.2

|

10

|

±25 |

*

|

|

|

500

|

13

|

13

|

*

|

25

|

±50 |

*

|

|

|

1000

|

25

|

25

|

*

|

50

|

±125 |

|

|

|

MATERIAL

|

Rockwell Hardness

|

||

|

Carbon Steel

|

AISI1010/1015

|

HRC 60

|

|

|

Chrome Steel

|

AISI52100

|

HRC 60-66

|

|

|

Stainless Steel

(Corrosion Resisting Hardened Steel) |

AISI440

|

HRC 58-65

|

|

|

AISI420

|

HRC 52min

|

||

|

Stainless Steel

(Corrosion Resisting Unhardened Steel) |

MAGNETIC

|

ASI 304/316

|

HRC 25-39

|

|

NON MAGNETIC

|

ASI 304/316

|

NA

|

|